Soil Treatment Centre for Hydrocarbon Impacted Soils

Summary

- Hydrocarbon impacted soils treated and diverted from landfill.

- Treated soils sent for re-use, better adhering to the Waste Hierarchy.

- Major cost reduction for client for disposal of contaminanted soils.

- Soils are treated by an enchance natural process which is adaptable to different types of soil and hydrocarbon contamination.

Background

Soil treatment centres divert hydrocarbon impacted soils from landfill by treating them with an enhanced natural process. This allows operators to better adhere to waste hierarchy, avoid landfill tax and save resources on landfill gate fees.

Geo² designed, built and installed a vacuum extraction system that enabled the safe operation of a soil treatment centre in the south of England. The client - an international waste management group - enjoyed major cost reductions all while adhering to environmental regulations, following the culmination of the project.

The Design & Build Phase

Our client sought a soil treatment centre that would allow for the renewal of 50,000 tonnes of hydrocarbon impacted soil per year. We ensured that these specifications, along with any other EA requirements were considered early on in the design phase.

The build was completed by our engineers within the timeframe agreed with the client. Once up and running the entire system was tested on soil inputs to the site, reducing the time of treatment to 16 weeks.

All site emissions were kept below targets set by the EA and the client during the treatment process.

Bio-degradation

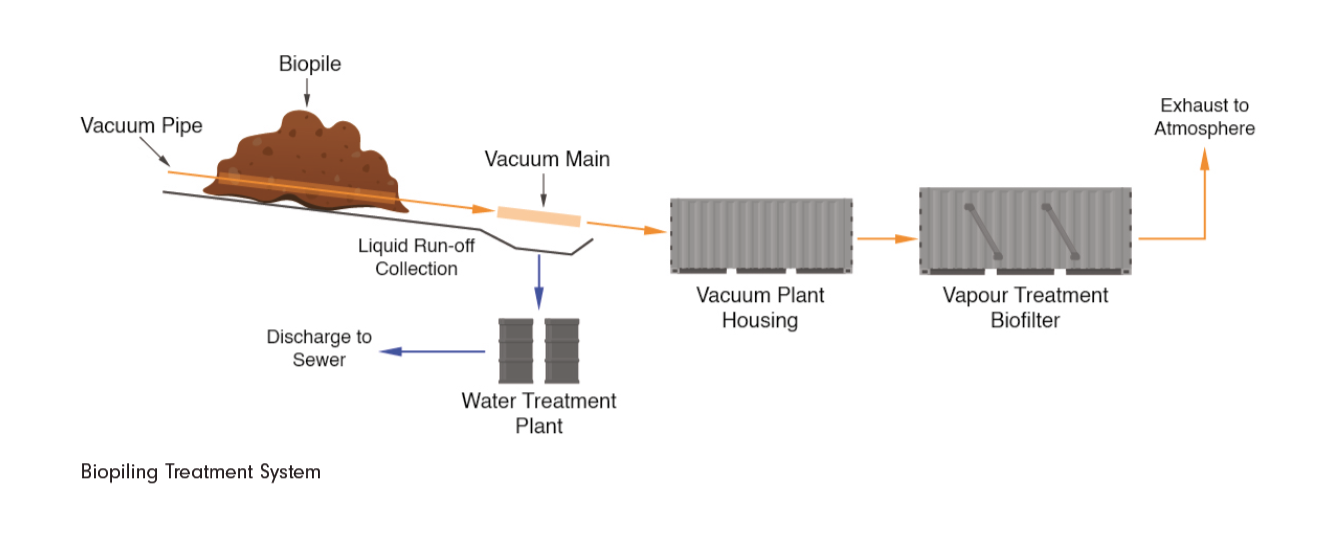

Aerobic biodegradation is a process in which naturally occurring bacteria in soils break down organic contaminants. The biodegradation process breaks down long-chain organics to volatile organics which are then drawn out by the aeration system and treated in the biofilter before being exhausted into the atmosphere.

The biodegradation process can be augmented by adding nutrients such as mature green waste to the soils undergoing treatment. Breaking up soils with a mechanical excavator can also help the aeration process.

Design & Build of the Vacuum Extraction System

Our soil treatment centre works on the principle of biological degradation of contaminants in soils, an entirely natural process which can be improved and sped up by aerating soils.

To achieve aeration of soils on the scale required, our team designed and built a bespoke air vacuum system capable of drawing 300m³/hr of air through a manifold 200m long, with 56 soil aeration pipes attached.

The vacuum aeration system was designed to be able to treat up to 15,000 tonnes of soil on the soil treatment centre pad at all times. As part of the build process to ensure quality, the installed plant was CE marked. To aid handover of the site, an extensive Operations and Maintenance manual was produced and delivered by our team, providing a suitable source of information for a smooth exchange of operations.

Running the Soil Treatment Centre

Once the soil treatment system was installed, Geo² also provided expert advice. We provided assistance to the client’s team of WAMITAB COTC technically competent managers some months after the build had culminated.

The programme of training provided by our team, selected because of their expansive experience with soil treatment centres, ensured that the site was up and running, treating inputs as soon as possible.

Guiding client site operatives over a period of 32 weeks, our team of experts demonstrated soil treatment techniques specific to soil or hydrocarbon contaminant types.

The STC system was tested under high stress conditions with heavily contaminated soils and was able to treat soils as required, while keeping emissions below agreed target levels.

The Soil Treatment Centre is now being run by the client, continuing to operate as designed by our engineers.