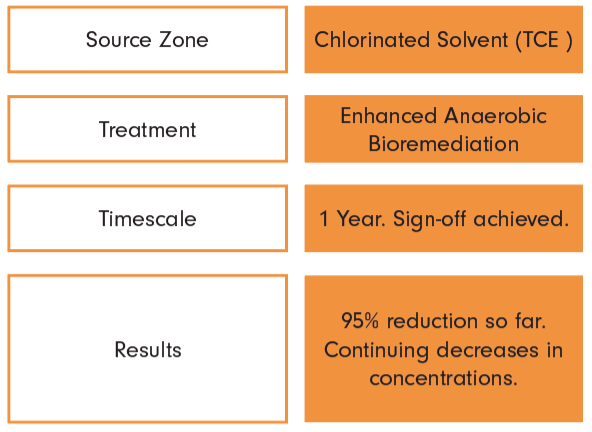

Enhanced Anaerobic Bioremediation of Chlorinated Solvents

Overview

Impact

A significant chlorinated hydrocarbon source was identified on a site in the north west which was undergoing redevelopment into commercial units.

Operational Restriction

The remedial strategy was designed to suit a tight development timescale, with works undertaken around, and during the ongoing construction of the industrial development.

Solution Design

Geo2 proposed a series of direct push injections of Hydrogen Release Compound (HRC), designed to accelerate the mechanism by which chlorinated hydrocarbons are biologically degraded under anaerobic conditions; a process known as reductive dechlorination.

Direct Injection Application

This in-situ treatment method minimises disruption to the ongoing development works using pressurised injection techniques to effectively target contaminants in a single application.

Rapid Results

Pronounced reductions were noted in the concentrations of dissolved phase TCE across the

site in a short time-scale.

Breakdown of daughter products, created as a result of TCE degradation, was also achieved over a longer timescale, demonstrating the ongoing activity of the HRC.

Regulatory Acceptance Achieved

- Over 95% of dissolved TCE contamination was remediated within 12 months.

- The project was completed with minimal disruption and no delay to the build programme

- Treatment successfully achieved the regulator approved objectives.

Detailed Evaluation

Contaminant

When redevelopment of an area of disused industrial land was proposed in an already heavily developed area, the discovery of a significant chlorinated hydrocarbon impact threatened to impact the development.

Geo2 were contacted to remediate the impact and ensure safe redevelopment of the site for a large scale industrial end use, whilst ensuring no liability to the future landlords.

An ongoing build programme required a robust and reliable solution, which could be applied quickly.

Rapid Targeted Application

Direct push injection, enabling pressurised application of chemicals at depth, was selected as the ideal

means of applying the treatment media. This technique requires no permanent infrastructure enabling building works to proceed uninterrupted whilst treatment occurred below ground.

By using specially adapted direct push drilling rigs, injections could introduce the treatment media at different levels throughout the water column, ensuring contaminants were accurately targeted, and maximum treatment was achieved from each injection.

Treatment Media

Geo2 proposed a series of direct push injections of Hydrogen Release. Compound (HRC), designed to accelerate the mechanism by which chlorinated hydrocarbons are biologically degraded under anaerobic conditions.

HRC is noted for its ability to break down Trichloroethylene (TCE) and its various daughter products. By injecting HRC in a grid configuration over the target area, saturation of the area was rapidly achieved.

Contaminant Reductions

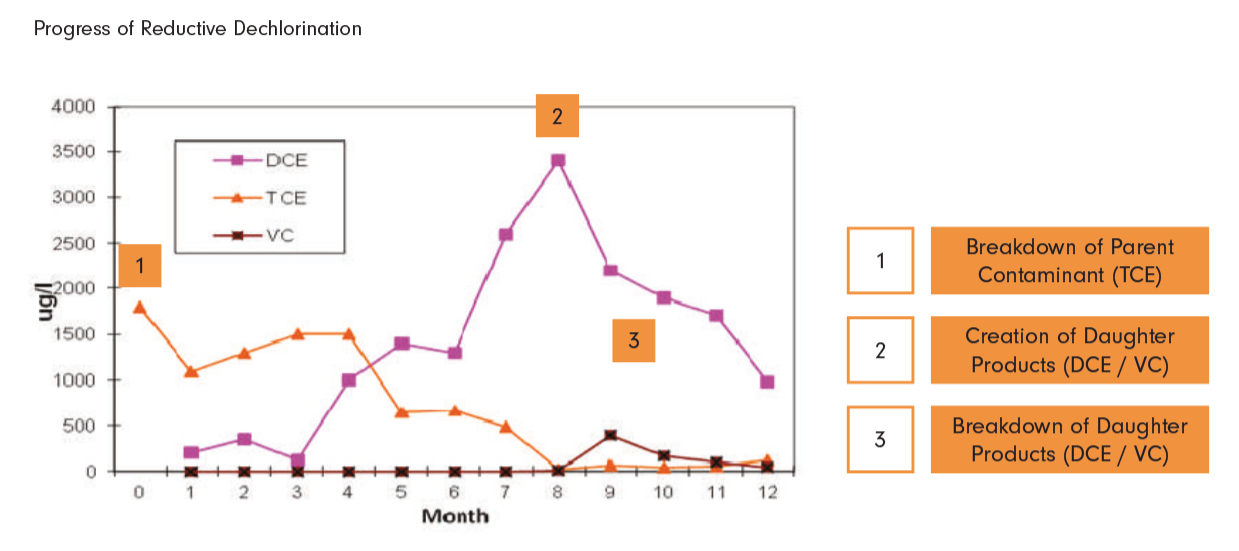

- Pronounced reductions were noted in the concentrations of dissolved phase TCE across the site.

- The breakdown products of this reaction, dichloroethylene (DCE) and Vinyl Chloride (VC) are considered to be similarly harmful, and therefore, remediation of these daughter products was also required.

- Significant reductions were identified in the most contaminated source locations, within 12 months of injection.

- In addition, the breakdown products of this reaction, DCE and VC, have showed reductions of over 65% and 85%, respectively, from peak concentrations.

Ongoing Degradation

Due to the long lasting and slow release nature of the HRC that was applied, breakdown of all these contaminants was predicted over the lifecycle of the HRC.

As the compound is active for up to three to five years, depending on the ground conditions, monthly monitoring trips were undertaken, which showed over 90% reductions in TCE.

By using this technique of application, the remedial potential of the HRC compound can be maximised, producing greater gains than would typically be achieved by implementing alternative methods. This technique enabled for accelerated in-situ bioremediation of the site to take place, whilst allowing redevelopment to continue, unhindered by on site remedial activities.