Total Fluid and Vapour Recovery Across a Commercial Fuel Station Following a Petroleum Release

Geo2 Remediation Ltd designed, built and installed a network of vacuum enhanced total fluid recovery system on the site of a significant loss of petrol and diesel fuel at a commercial petrol filling station in the North of England. Free petroleum product and extremely flammable vapour contamination were uncovered during the site re-development, located on the site of a historic surface coal mine.

Geo2 provided on-site expertise in the initial delineation of the contamination, site supervision and materials management during hotspot removal and design and implementation of an adaptable remediation system. Remediation is ongoing and designed to provide flexible and focussed remediation of a multi-fuel oil plume of both free and dissolved phase petroleum product below an operational fuel distribution facility.

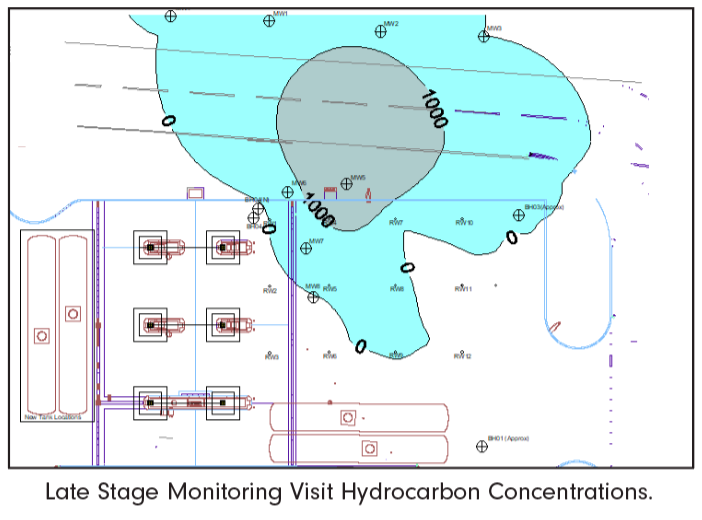

Treatment has reduced total contaminant load on site in the initial period of operation from 20mm of product to light sheening with multiple treatment wells previously impacted by free product now presenting contaminant levels less than laboratory detection limits.

The in-situ remediation strategy has had several positive sustainability outcomes including reducing mass material movements off site through targeted hotspot removal, creation of a pumped groundwater barrier isolating the contamination within site boundaries and protection of the wider environment and offsite residential receptors from negative emissions often associated with hydrocarbon remediation (noise and odour).

Site Context

The commercial fuel distribution site is located in a highly developed residential and industrialised area of the North of England. Built on the spoil heaps of a former surface coal mine, the site has been under recent modernisation. Geo² Remediation Ltd were called out to attend and assess following an emergency call-out from the site re-developer following the identification of extensive petroleum product contamination and strong petroleum vapours in the vicinity of the fuel storage areas on-site.

Site Geology and Hydrogeology

The sub-surface conditions of the site comprise extremely heterogenous mixtures of coal ash, slabs of mudstone and fractured sandstone blocks bound by an unstable clay matrix to depths of 20+ metres below ground level. This has created an unpredictable and uneven groundwater surface across site with areas of near surface groundwater mounding in places and dry stratigraphy in others. The coal bearing, mined bedrock on site is estimated to be up to 15m below ground level.

Contamination

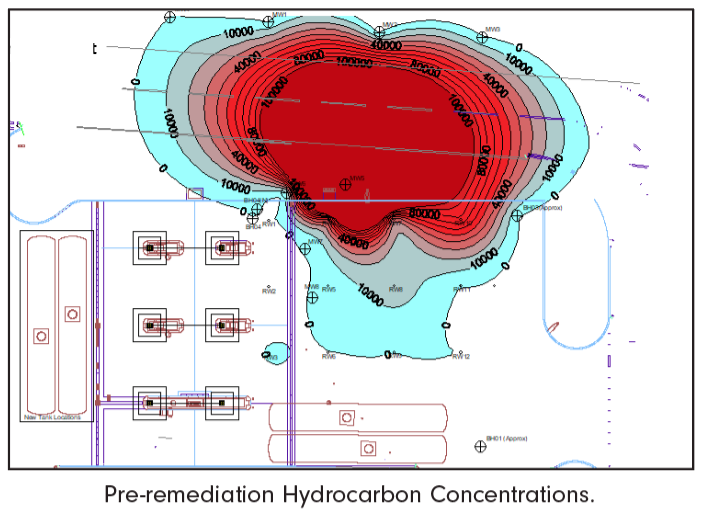

Early trial pit investigations and detailed rotary drilling investigations identified a dissolved phase plume around 100m³ in area migrating south-east from the site towards a residential area. The core of this plume centred around a set of fuel distribution islands on the historic forecourt with a free petroleum product (degraded diesel) around the leak point.

Environmental engineers on site found seriously elevated, flammable petroleum vapours and weathered product seepage in the clays to depths of 5m below ground level. The contamination was found in pockets and voids within the unevenly layered soils making assessment a challenge. Free product was found flowing out of dark lenses of coal ash and tipped slag.

Remediation Strategy

Geo² provided specialist remediation advice to the site redevelopment contractor including how to safely work with petrol contaminated soils. A dynamic remediation strategy was designed and implemented following regulator agreement.

This included:

- Highly selective hotspot excavation of the ‘plume core’ where free petroleum was found seeping out of the soil structure to reduce total movement of waste off-site with ex-situ stockpiling and soil venting;

- Installation of a closely spaced array of remediation boreholes and ducts across the plume area;

- Operation and installation of a soil vapour vacuum recovery system to prevent vapour release;

- Abstraction from a network of in-situ groundwater pumps on ‘focused’ wells compliant with local abstraction restrictions;

- Creation of a temporary in-situ pumped groundwater barrier on-site to isolate any migration of the plume off-site.

Results

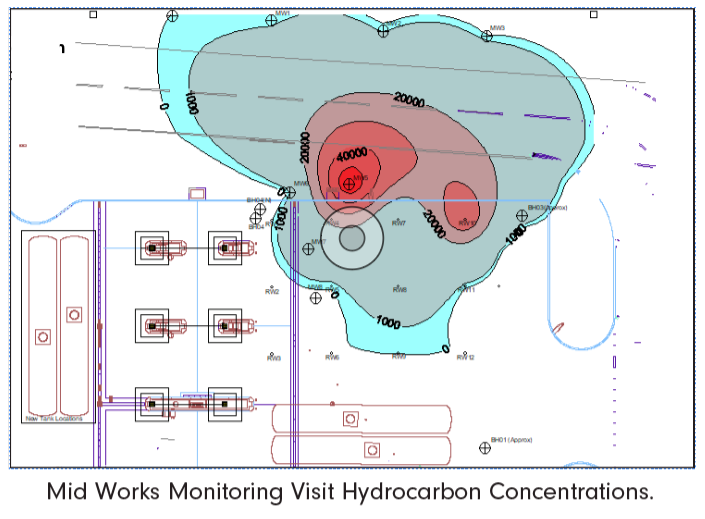

The groundwater remediation system has pumped ~1500 m³ of contaminated groundwater to date, stopping the migration of the plume of both soil vapour and fuel oil off-site. Groundwater concentrations of total petroleum hydrocarbon (Σ TPH) have been reduced from in excess of c.300,000 mg/L to 1050 mg/L . Volatile Organic Compound measurements on site have been vastly reduced from 3000ppm to <80ppm in the sub-surface. This has enabled the continued operation of the site and the protection of nearby homes.

Moving Forwards

Geo² Engineers regularly monitor the level of contamination and vapour in the ground and groundwater under the site. The site will continue to be monitored until the point where Geo² Environmental Scientists and Regulators are happy that the site is in a condition which will not pose a risk to the environment or local residents!